Converting

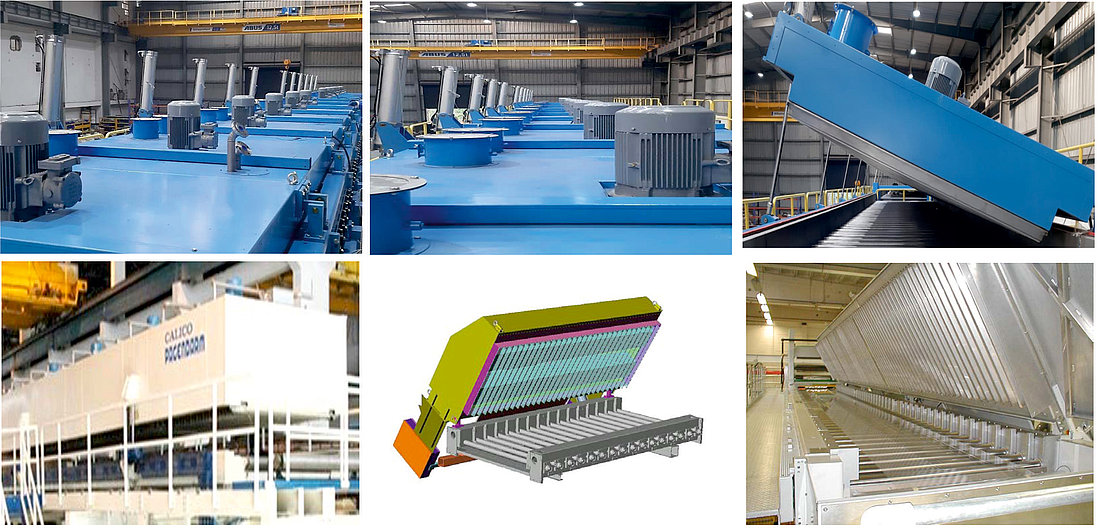

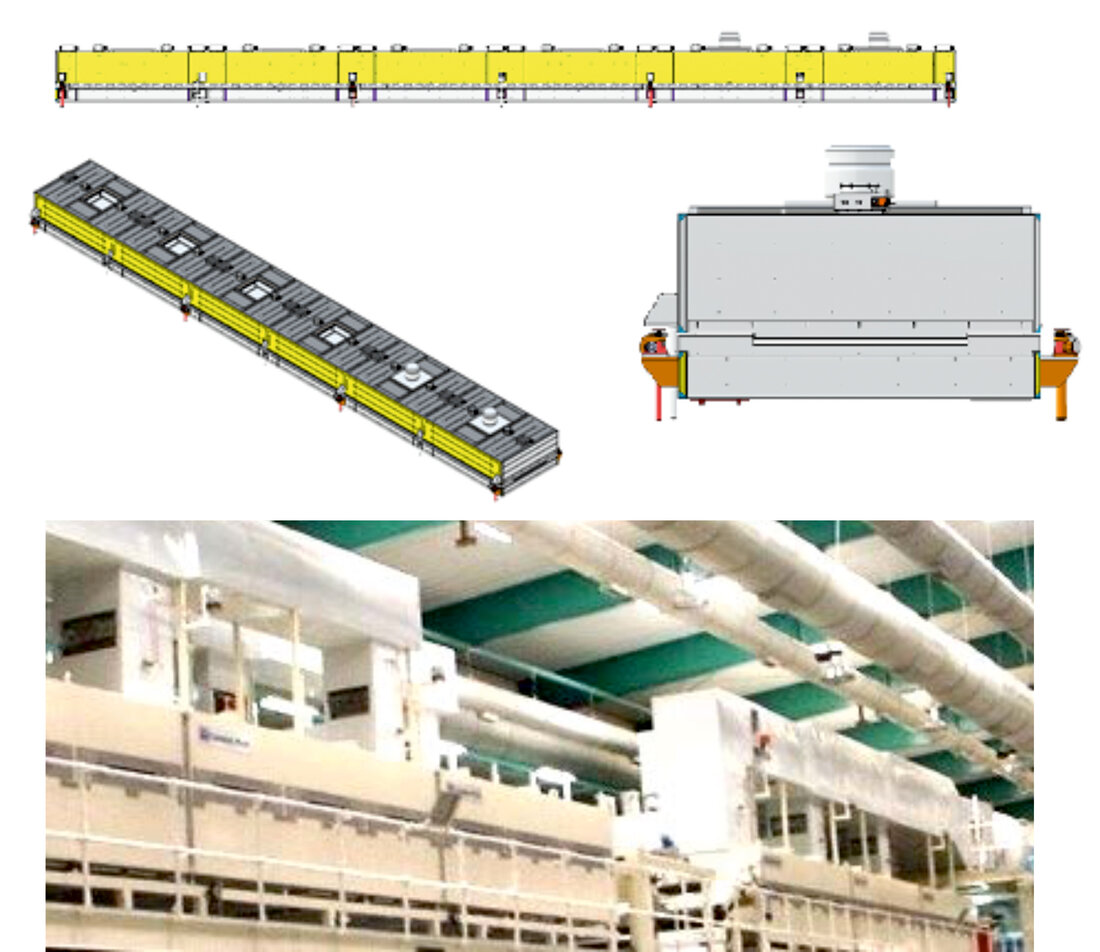

Dryers

The dryer is the second major element in determining production quality and cost-effectiveness.

Kusters Calico offers innovative drying systems for both powerful and kind to the product, while ensuring a consistently stable web position. When drying solvent resistant coatings, adjustable with nozzles and adjustable nozzle slits optimize drying performance and reduce energy consumption. When drying thick film coating, the combination of nozzles prevents premature skin formation and creates a blister free transparent product.

Every application has its own specific requirements and needs a coordinated drying system to obtain the best possible result. The appropriate drying system, nozzle configuration and type of heating are vital select the ideal control system. This simplifies the drying process and optimize adjustability. We offer application oriented dryer that fall.

Roller Support Dryers

Kusters Calico supports roll dryer with its individually driven support roll is integrated directly into the system's machine frame. This design requires no additional installation space.

The regulated AC drives - controlled motors are located on the dryer substructure. Stretch resistance flat belt ensure the support rolls operate smoothly for optimum web transport, even with the thinnest of materials. The roller bearings integrated in the cold parts of the support struts and thus cooled by surrounding air also contribute to this. They required no additional lubrication at any point in their service life. Easy maintenance of all load bearings points is possible from the outside. The support rolls made of hard chrome plated steel are suitable for drying air temperatures of up to 300 degrees Celsius.

Air Flotation Dryers:

Air Flotation Dryer has separate air circuits for the upper and lower nozzle banks. The circulating air returned via generously dimensioned central extraction ducts between nozzles. This design principal ensures a stable web position and uniform temperature over the working width. When drying solvent-based coating this technology also ensures LEL compliance throughout the dryer field.

Web tension throughout the entire air speed range, giving outstanding web stability and low shrinkage high performance with perfect web stability and completely uniform drying guarantees maximum production reliability, quality and cost effectiveness. In air flotation dryer the edge of web remains 'rock-steady' in the airstream. Clean nozzles rims are a sign of drying quality.

Kusters Calico offers radiation curing UV, IR and EB system for coating applications. We have close collaboration with industry experts and suppliers for such project required specialized curing systems. Our solution of radiation curing system are easily installed in to any existing coating line and starting up at customer plant.

We ensure perfect heating for your process, whether gas, thermal oil, steam or electricity, we have the ideal heating method for any application. The method is selected based on the application and taking into account the drying requirements and cost/energy efficiency.

Technical Data:

| Material: | Plastics Film and Paper |

| Width of the Machine: | 850 mm /2500 mm |

| Machine Speed: | Up to 400m/min |

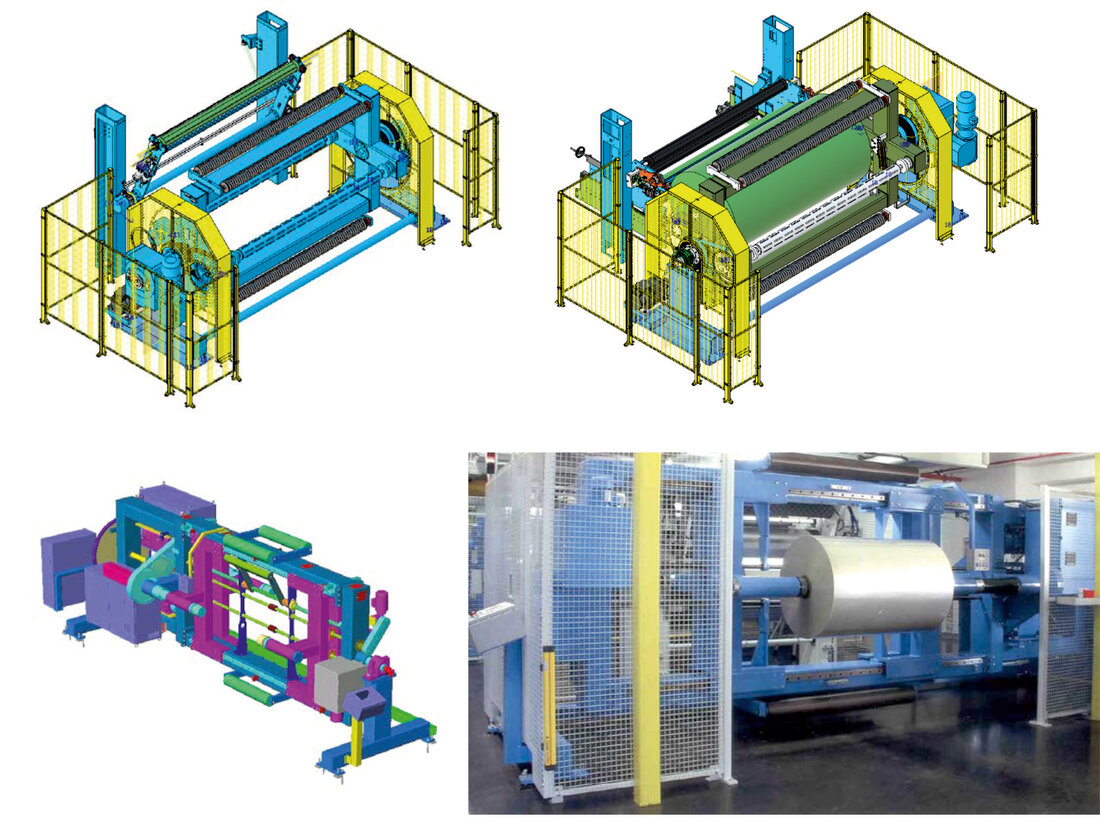

Winder

Kusters Calico has application oriented winder solution to optimize and address the specific task required. We believe in optimum performance and high availability for winder over it entire machine life. We have integrated structure for our shafted/shiftless turret winders with advanced hardware and software platform. We upgrade your old existing winder and have longer life. The new technological system offers maximum performance through modern remote service feature enable almost no downtime with added safety. Our winder portfolio is suitable for varied application and can be used for turret and single winding system. Through an upgradation you achieve more productivity and advance level automation.

Technical Data

| Material: | Plastics Film and Paper |

| Width of the Machine: | 850 mm /2500 mm |

| Machine Speed: | Up to 400m/min |

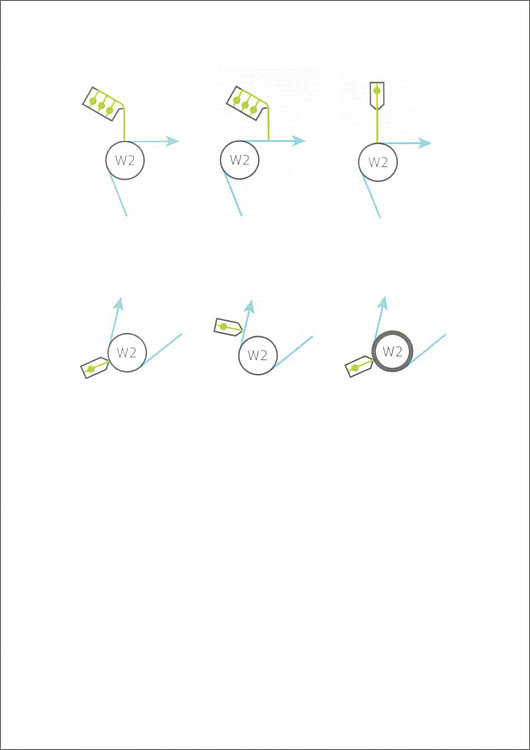

Coating Head

Kuster Calico has right coating head for every coating. The technological design of the coating system is tailored to the special requirements of the individual compounds. The quality of the end product results from perfect interaction between mechanical precision, innovative control logic and our know-how.

The precisely adjustable coating heads ensure reproducible quality for coating width of few millimeters to several meters with coat weight of 0.3 GSM to 500 GSM at speed of 10 to 350m/min. Coating head on movable trolleys can be outside the machine in preparation for production changes and then moved into working position in matter of minutes.

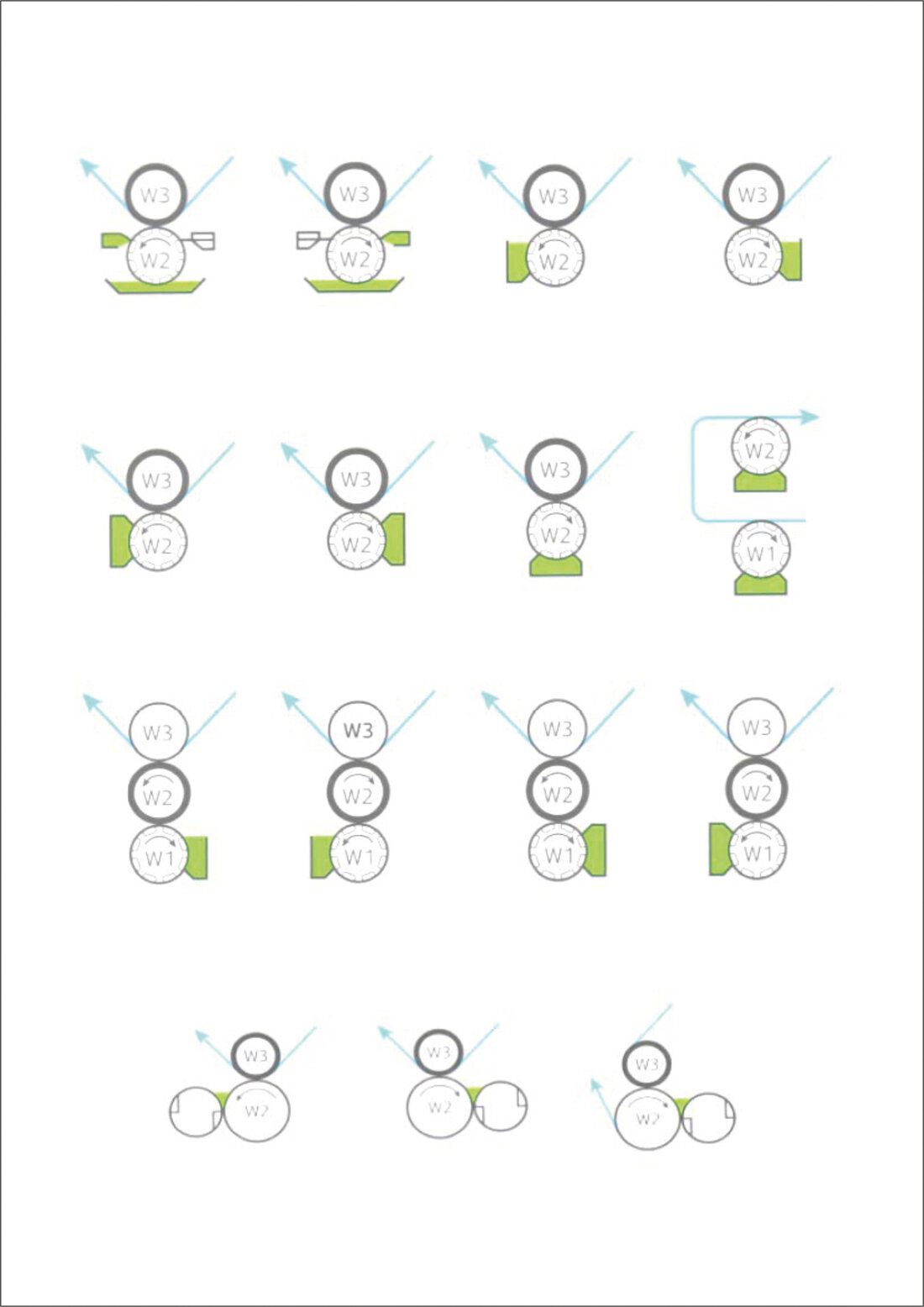

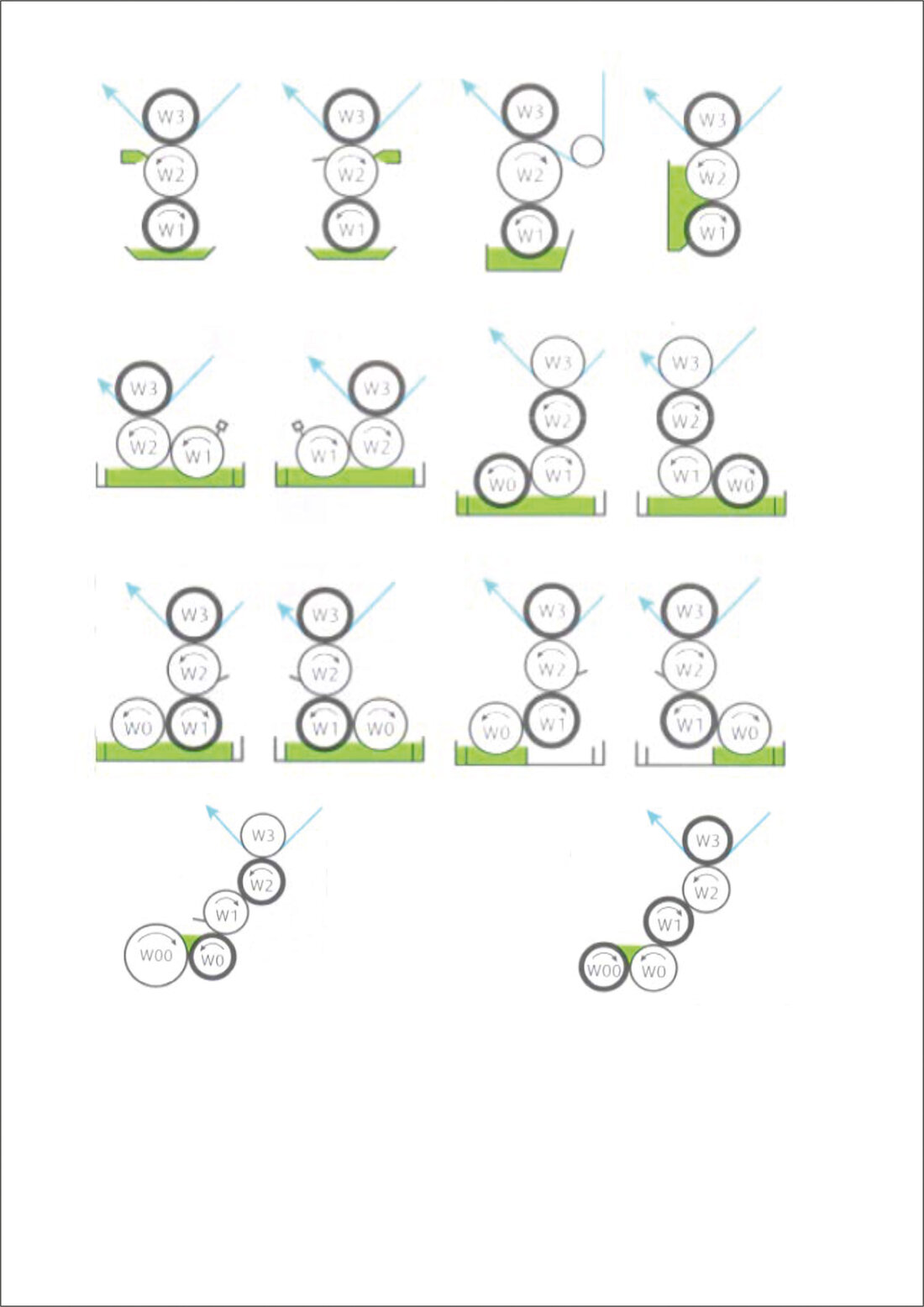

Self-metered Coating system

Kusters Calico offers wide range of self-metered coating system includes Gravure, Smooth Roll with Nip metering & GAP metering. The gravure coating system are workhorses of coating process. Combining a simple structure with versatility, our gravure coating system cover a wide range of coating applications and enable customized unit design. Gravure roll systems are best suited to coating films, paper and foils with water/ solvent-based lacquers.

The layer thickness that can be achieved depend on the gravure pattern, the direction of roll rotation and lacquer properties. Roll with ceramic coating extend the production time several times over. Typical coating of wet thickness of 0.1 to 50 GSM, viscosity up to 400mPas, coating tolerance of 3% to 5% at speed of 350 m/min.

The basis configurations available include various doctor blade and feeding system, which can be installed at various position on the gravure roll.

Our smooth roll system with nip metering are best suited to coating substrates with water or solvent based media. The layer thickness that can be achieved depend on the number of rolls, the direction of roll rotation and rheological lacquer properties. The basic versions available include nip and pan feed system. The typical wet coating thickness of 0.3 to 50 GSM, viscosity of 50 to 3000mPas, coating tolerance approx. 5 to 10% at speed of 350m/min.

Smooth roll systems with GAP metering are universal coating systems. Their specific roll arrangement with various feed systems makes specialist of coating units. They range from basis two roll coating unit to complex comma doctor system. Smooth roll systems with gap metering are best suited to coating films and foils with water or solvent based lacquers and adhesives.

The typical wet coating thickness of 3 to 500 GSM, viscosity up to 3000mPas, coating tolerance approx. 7 to 10 % at speed of 150 m/min.

Post-metered Coating system

Kusters Calico offers wide range of post-metered coating system includes Mayer bar and Air Knife. These systems are best suited to coating films and foils with water or solvent based lacquers and adhesives.

The typical wet coating thickness of 3 to 500 GSM, viscosity up to 3000mPas, coating tolerance approx. 7 to 10 % at speed of 150 m/min

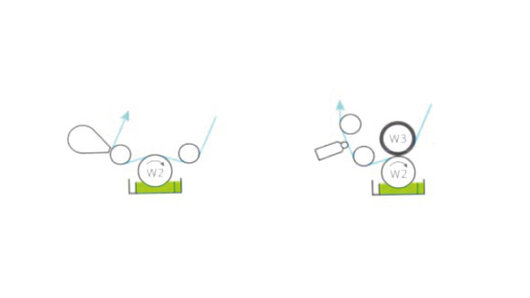

Die Coating system:

The Die systems include Slot, Slide and Curtain coating systems now rank among the coating systems of choice for customers with high demands in terms of coating quality and production speed. The great strength of the die systems lies in their linear ability to apply several coating in single pass. Individual functional layers can be as thin as 1 micron. The curtain coating system produces multilayer coating with longitudinal and transverse profiles that satisfy even the toughest demands.

Die systems are best suited to coating films, paper and foils with water and solvent based lacquers and adhesives or 100% systems. They are also used for two component systems where the components mixed directly at the die inlet. The system configuration for handling complex tasks is based on the process know-how of experts. This covers the entire process flow from liquid preparation to mixing and degassing. Typical wet coating thickness of 10 to 500 GSM, viscosity up to 30,000mPas, Coating tolerance approx. 0.2 to 2 % at maximum speed of 500 m/min.