Bleaching

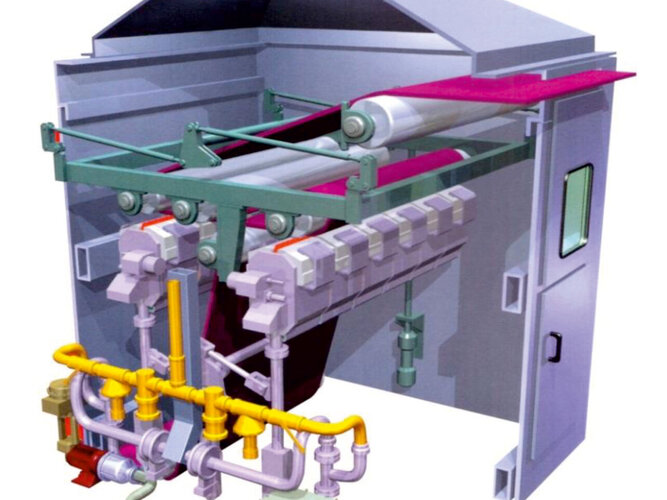

Steamer for bleaching process

- Steaming is an important process in every continuous pre-treatment and dyeing plant.

- Steam allows fast energy transfer directly into fiber.

- During the bleaching process it is necessary to expose the fabric to sensitive but effective treatment.

- We satisfy the need of a successful process cycle by means of machine technology that offers a safe guiding of material, which is adapted to the fabric and which is essential in the application of chemicals, the steam conditioning and the dosing technology.

- Our bleaching ranges perform the bleaching process in optimum conditions that guarantee a fabric of corresponding degree of whiteness and high degree of absorbency.

Concept

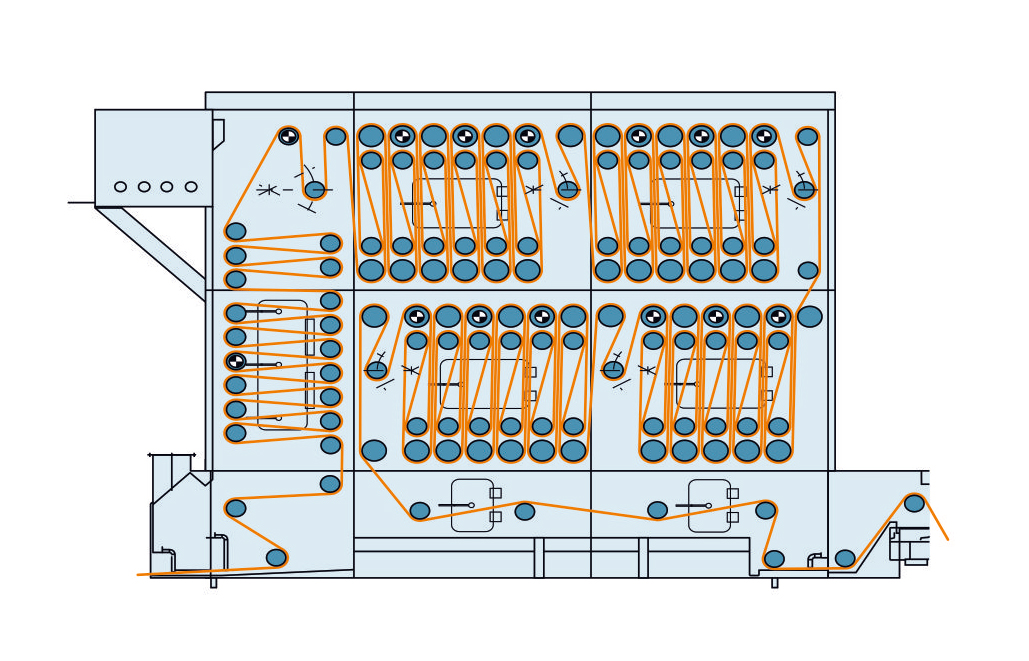

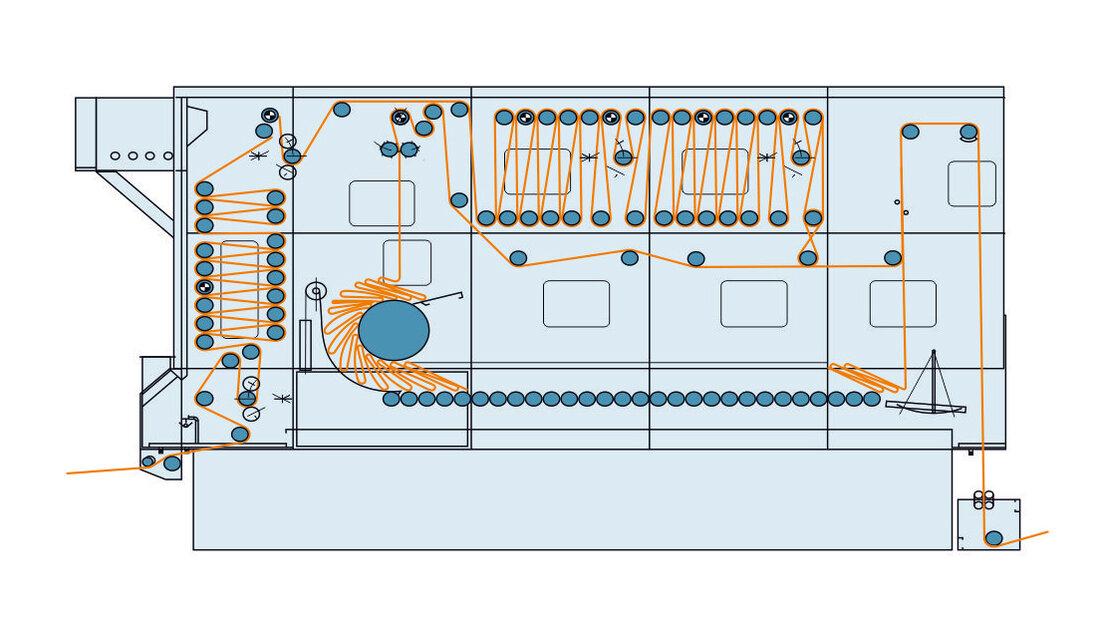

- Bleaching consist of section with tight strand fabric guiding and roll bed.

- In tight strand section the fabric which has been impregnated with the bleaching liquor is heated up as per the requirement and on roller bed we maintain sufficient dwelling time for reaction purpose.

Brief Specification

- Dwelling section pulling device, plaiter, reversing drum for plaiting on roller bed.

- Roller bed with driven pulling rollers.

- Exit section with sensible blade.

- By pass device for the roller bed. (Optional)

Bleaching Steamer

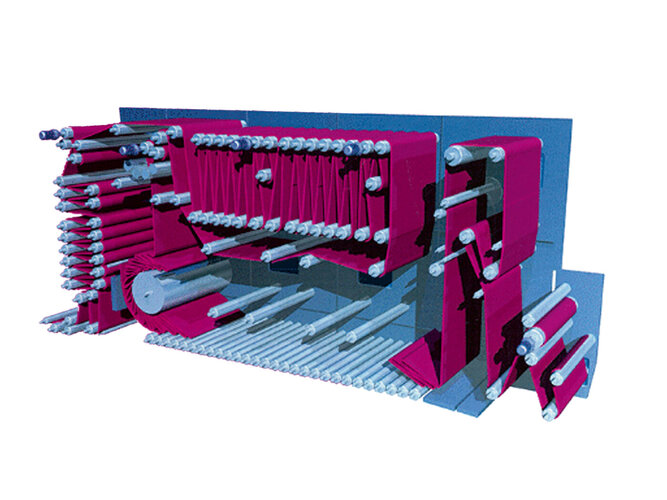

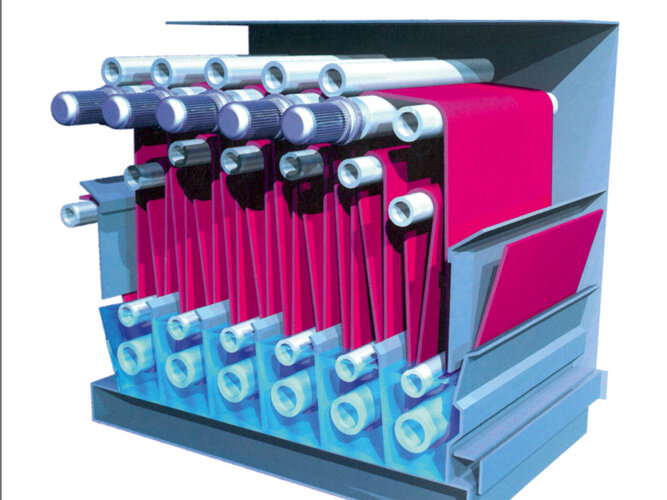

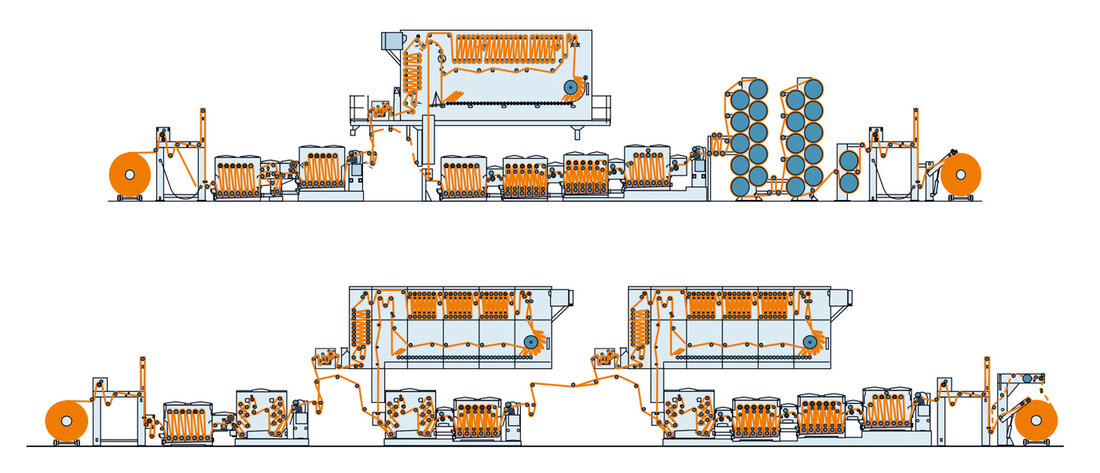

Two-Level Steamer

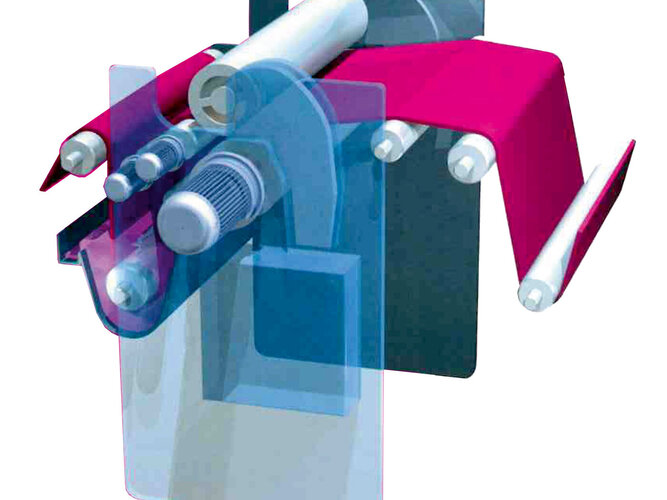

The Two-Level Steamer with its tight-strand fabric guiding will be used mostly for sensitive fabrics. Many driven pulling rollers in combination with pendulum compensators guarantee low fabric tension.

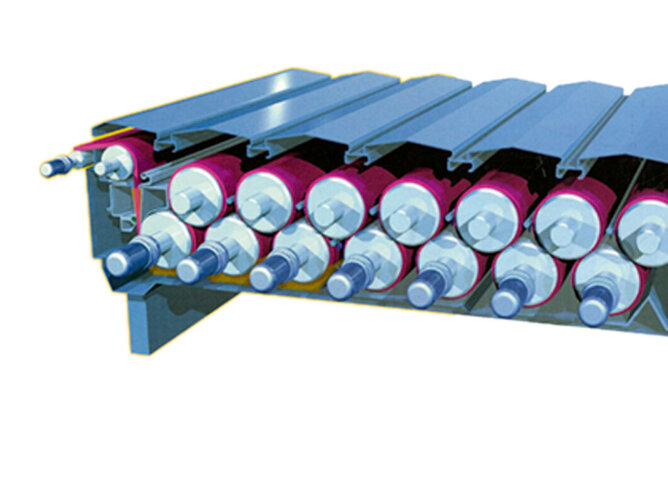

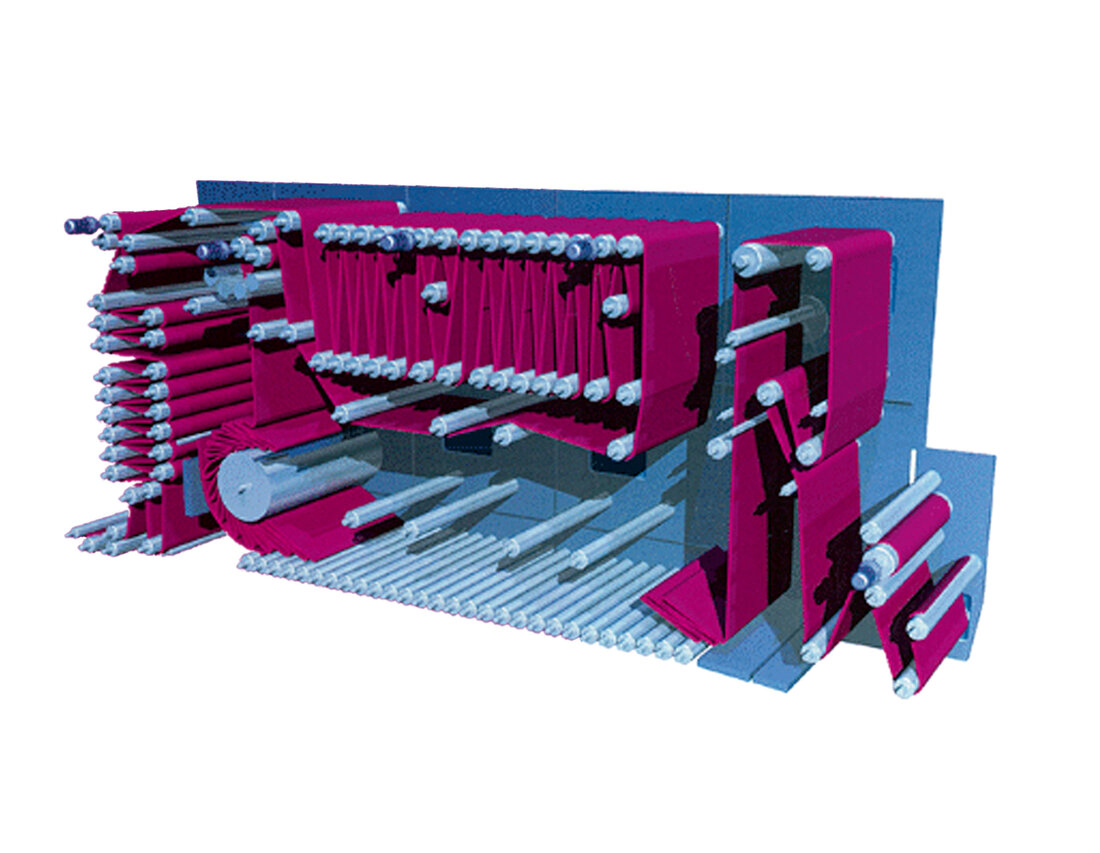

Rollerbed Steamer

Rollerbed steamers consist of sections with tight-strand fabric guiding and the Rollerbed. In the tight-strand guiding section the fabric which has been impregnated with the bleaching liquor is heated up. On the Rollerbed there is sufficient time for the bleaching reaction process.

The Rollerbed steamer offers storage room for big quantities of fabric with long steaming times by small construction dimensions.

Dwelling section with pulling device, plaiter and reversing drum for plaiting on the Rollerbed.

Rollerbed with driven pulling rollers.

Exit section with sensing blade. Optional by-pass device for the Rollerbed.

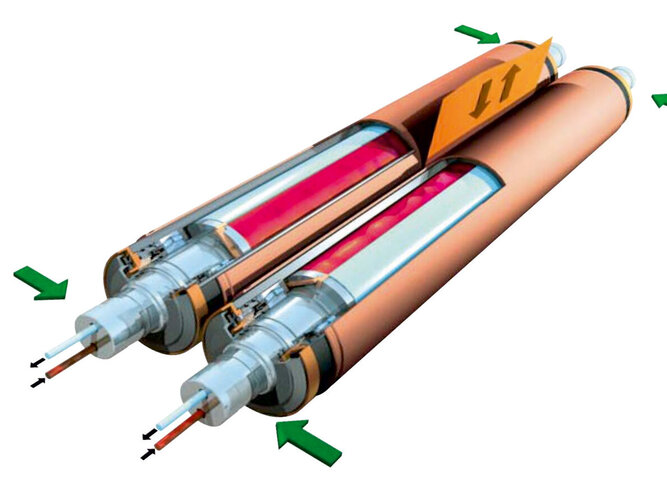

Contidos Dosing System for Bleaching

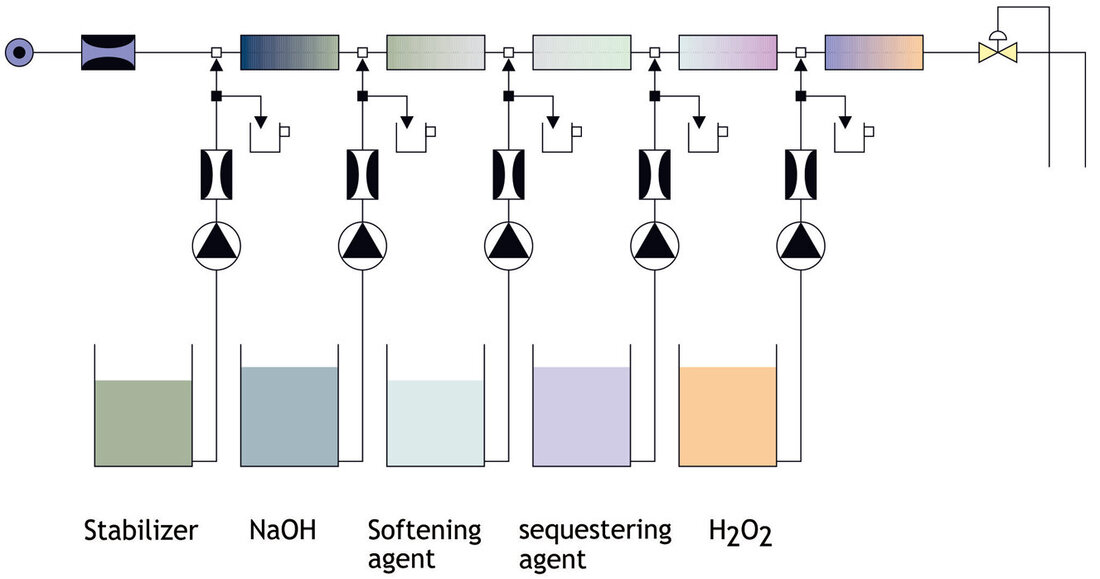

Online Dosing for Bleaching

- Continuous production of treatment liquor on the basis of water and the separately dosed auxiliaries

- All auxiliaries, including water, are blended homogeneously in a mixer and fed into the padder and into Shaft Applicator

- Dosing of auxiliaries according to recipe in ml per kg of fabric