Mercerizing

This is a process in which textiles (typically cotton) are treated with a caustic (NaOH) solution to improve properties such as fibre strength, shrinkage resistance, luster and dye affinity.

Mercerizing has become an important step in the textile pretreatment of cotton.

The advantage of mercerizing are as follows:

- Less dyestuff-consumption

- More color depth

- Higher brilliance

- Higher tenacity

- Better tear resistance

- Better handle

- Appearance

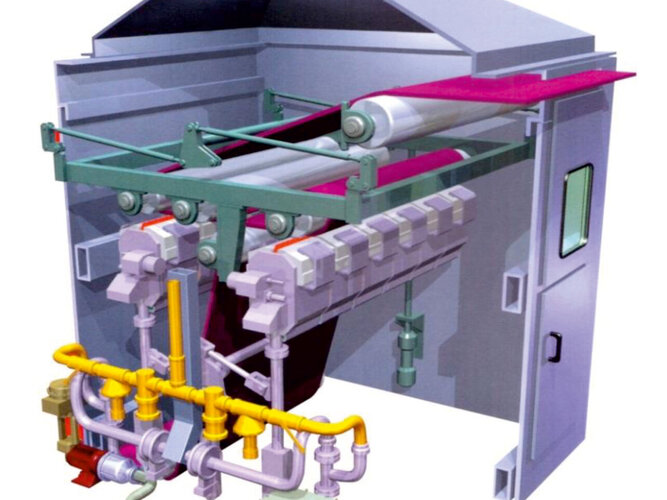

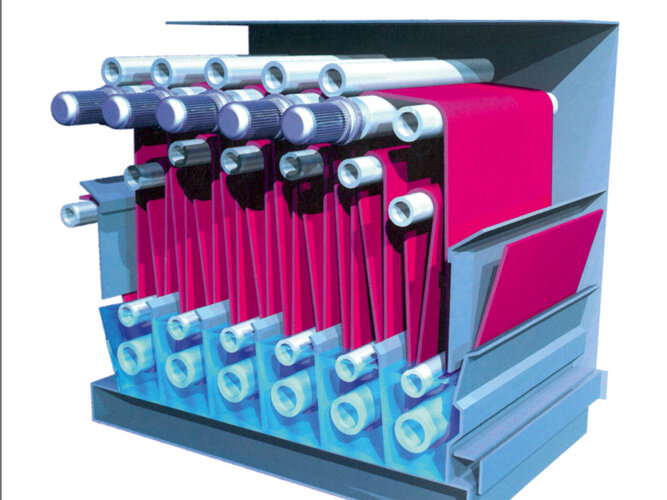

Chainless Mercerizing

Chainless mercerize is equipped with :

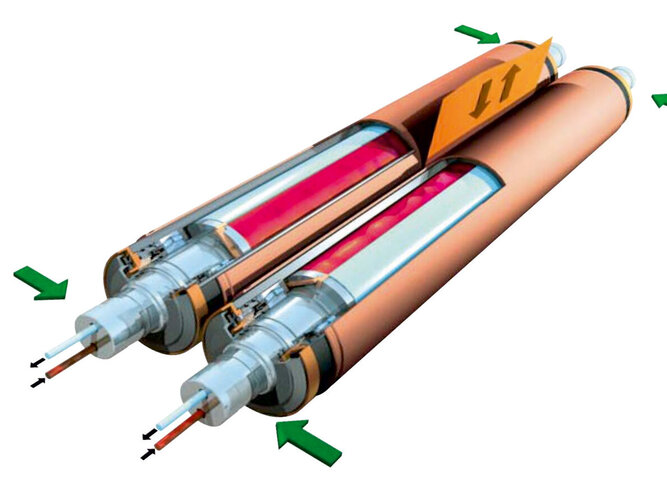

- For wet on wet mercerizing, S Roll squeezer before impregnation, which results in lesser exchange of moisture with caustic and lesser consumption of caustic soda.

- Caustic soda circuit with mixing trough, pumps and heat exchanger.

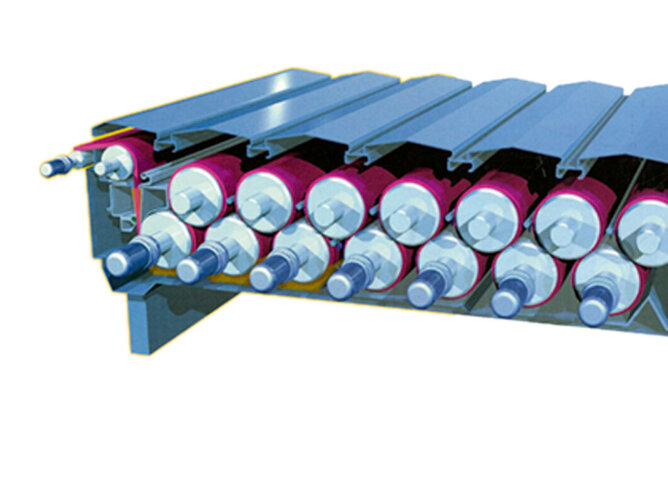

- Impregnation compartment is with stainless steel modular concept.

- Driven bottom rollers for better fabric tension control and stretching in warp direction.

- After impregnation, S Roll squeezer to minimize caustic consumption.

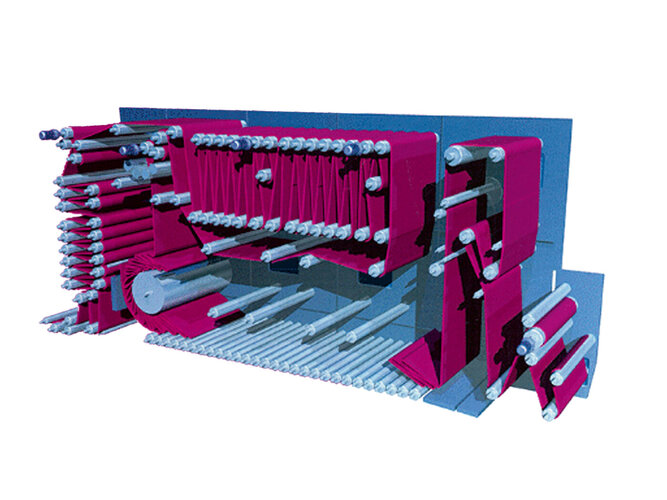

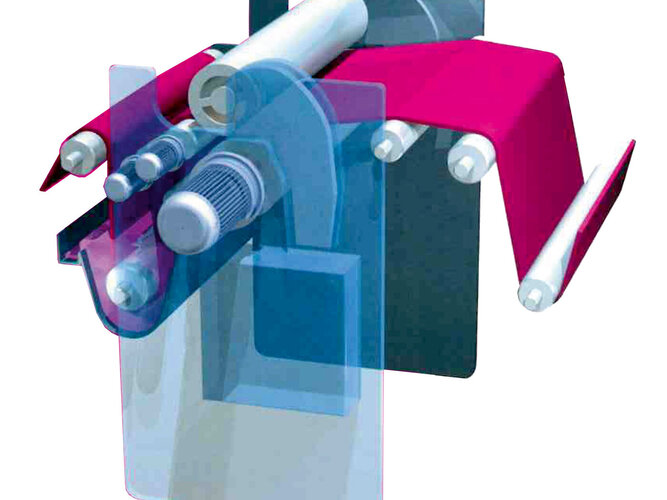

Chain Mercerizing

Chain mercerize is equipped with:

- For wet on wet mercerizing, S Roll squeezer before impregnation, which results in lesser exchange of moisture with caustic and lesser consumption of caustic soda.

- Caustic soda circuit with mixing trough, pumps and heat exchanger.

- Impregnation compartment is with stainless steel modular concept.

- Driven bottom rollers for better fabric tension control and stretching in warp direction.

- Width stretching zone with web tension measuring unit, 2 pair of chain with pin or clip unit for uniform and reproducible stretching in weft direction.

- After impregnation, S Roll squeezer to minimize caustic consumption.