Lamination Machine

Kusters Calico web lamination machines are proficient in laminating multiple web of Foil, Film, Paper and other roll based web materials. New generation lamination lines for Solvent based, Solventless, Water based and hot melt media with advanced automation to enhance productivity and profitability. We design and built the custom lamination line using any film and adhesive.

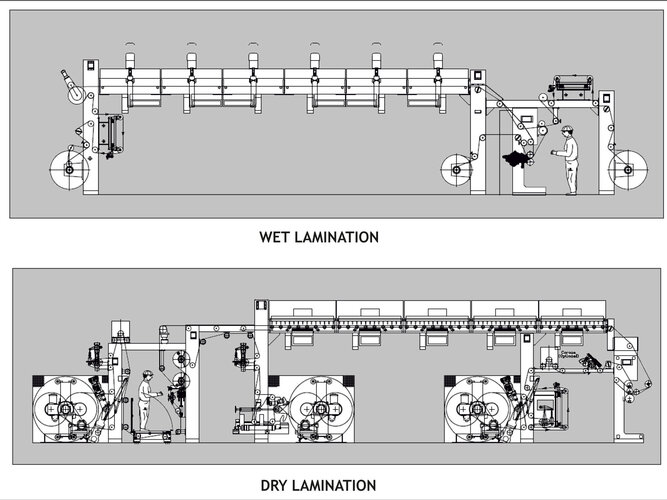

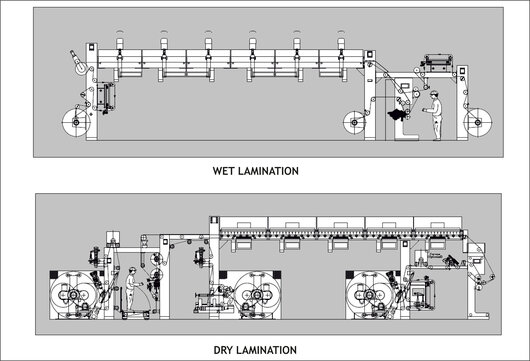

Dry and Wet Bond

The most favoured lamination process, our Dry & Wet bond laminator is multipurpose for film, foil and paper. The advantage of dry lamination includes high resistance to the chemical medium corrosion, available for tough packaging condition requirement. The wet lamination provides effortless lamination process for various kind of paper product application. The available application included paper, foil and plastics. The advantage of wet lamination as it low running cost, high production and low investment.

Technical Data

| Material: | Plastics Film and Paper |

| Width of the Machine: | 850 mm /2550 mm |

| Machine Speed: | Up to 400m/min |

Solvent based

Kusters Calico offers the specially designed solvent based lamination line for lamination of flexible packaging substrates like plastics, foil and paper. Kusters Calico offers lamination system for duplex and triplex for variety of multi-layer structure to the customers.

Technical Data

| Material: | Plastics Film and Paper |

| Width of the Machine: | 850 mm /2550 mm |

| Machine Speed : | Up to 400m/min |

Solventless

Kusters Calico offers high performance solventless lamination that provides precise adhesive coating at desired speed. The proven five roll adhesive coating system, accurate metering system, unique lamination nip and précised web tension control system ensure uniform roll to roll lamination.

Technical Data

| Material: | Plastics Film and Paper |

| Width of the Machine: | 850 mm /1750 mm |

| Machine Speed: | Up to 400m/min |