Textile

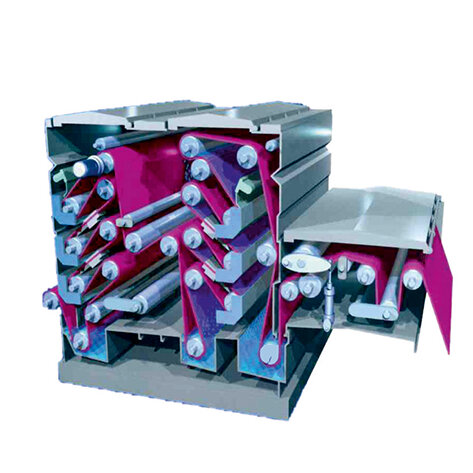

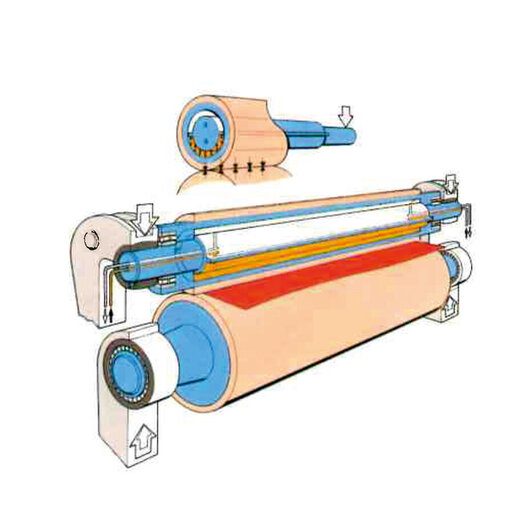

S-Roll

S Roll has revolutionized textile industries, thanks to its unique patented concept of antideflection. S Roll technology is the small diameter and the fact that there is no need for any crowned roll. This guarantees a maximum specific pressure, an absolutely even squeezing effect over the entire width of the roll nip, controlled even or uneven linear pressure.

With such advantages, Kusters Calico is taking retrofitting job of existing machines of all wet processing manufacturers wherein old squeezers can be replaced with S Roll squeezer to enhance process results.

Some of the examples:

1. S Roll after impregnation process on mercerizing can lead to even penetration of caustic soda through out width of fabric as well as higher squeezing load which results in more squeezing of fabric and lesser caustic soda consumption.

2. S Roll before impregnation process can lead to lesser dilution of moisture of caustic soda during impregnation process on mercerizing.

3. S Roll finishing squeezer before stenter frame can lead to lesser residual moisture on fabric as well as even finishing application.

4. S Roll squeezer in front of drying range, can increase production due to increase in even squeezing which result in lesser steam consumption also.

There are the some of the examples, please contact us to improve existing production range with S Roll. We can offer all technical services including preparation of drawings, technical consultation and realistic production data based on our wide experience to enhance your existing ranges with S Roll technology.

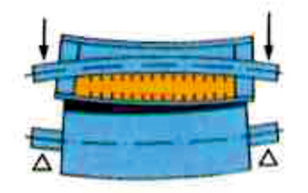

Dewatering

Dewatering-Though suction.

Vacuum technology for efficient stream separation for recycling of application liquor or for contamination level reduction. Separate disposal of heavily contaminated effluent reduces water for the next washing processes. Following are the advantages of suction/vacuum technology:

1. Separate disposal of heavy polluted liquor.

2. Increased washing effects in the downstream washing units due to high concentration liquor separation.

3. Possible recovery of size or chemicals.

4. Lower residual moisture content on many synthetics fabrics and blends.

5. Shorter wash ranges, depending on the process.

Due to compact in size, vacuum unit can be installed in existing range to enhance productivity of the machine. Please contact us to improve your existing production range with S roll. We can offer all technical services including preparation of drawings, technical consultation and realistic production data based on our wide experience to enhance existing ranges with vacuum/suction technology.

Washing

In textile finishing the washing process play a decisive role. For desizing, after bleaching, after mercerizing and after dyeing it is necessary to wash out residual chemical and dirt particles. So during finishing, each textile undergoes several washing processes. Washing, therefore, has a significant influence on the quality of the finishing step.

Kusters Calico is well aware of this and, always consider high importance to washing. Super flush was developed to serve beyond the basic washing machine up and down washers. It distinguishes itself by excellent fabric passage properties that play decisive role for demanding and delicate crease prone articles.

Kusters Calico can offer their expertise in processing of various textile article and can suggest suitable washing compartment for your existing machine. Depends upon the process we can offer following compartments:

Spares

Whether preventive maintenance, repair, after sales or Swimming Roll service-all are provided by Kusters Calico. The highly qualified engineers and technicians with years of experience execute their work at highest possibly standards. We provide quality and based on the technology and manufacturing know-how of former Eduard Küsters Maschinenfabrik.

Each machine is delivered with detailed catalogue of consumable spares stored in HMI of the machine, and HMI are programmed to generate message on service screen for lubrication intervals and life span of consumable spares, so technician can change the consumable spares before it is due for replacement and avoid machine stoppage.

Kusters Calico has invested lot of resources to provide after sales service for Swimming Roll. Expert technicians are working on servicing of the Swimming roll and each Swimming Roll are checked with real production set up at our factory itself, enabling customer to install directly on their machine after servicing of Swimming Roll without wasting of time for various trials to achieve even pick up values.

Our customer support team is available 24X7 to support our customers, for any query

Contact: spares@kusters-calico.com